Our customer Van Hoecke (Sint-Niklaas, Belgium) makes a point of delivering tailormade TA’OR drawer boxes within three working days. This means that there are only 72 hours between order intake and delivery. Each type drawer box is available in a wide range of colors, materials and dimensions. The catalogue consists of 48.000 billion possible variants. No wonder they keep a super tight production schedule. Every minute counts!

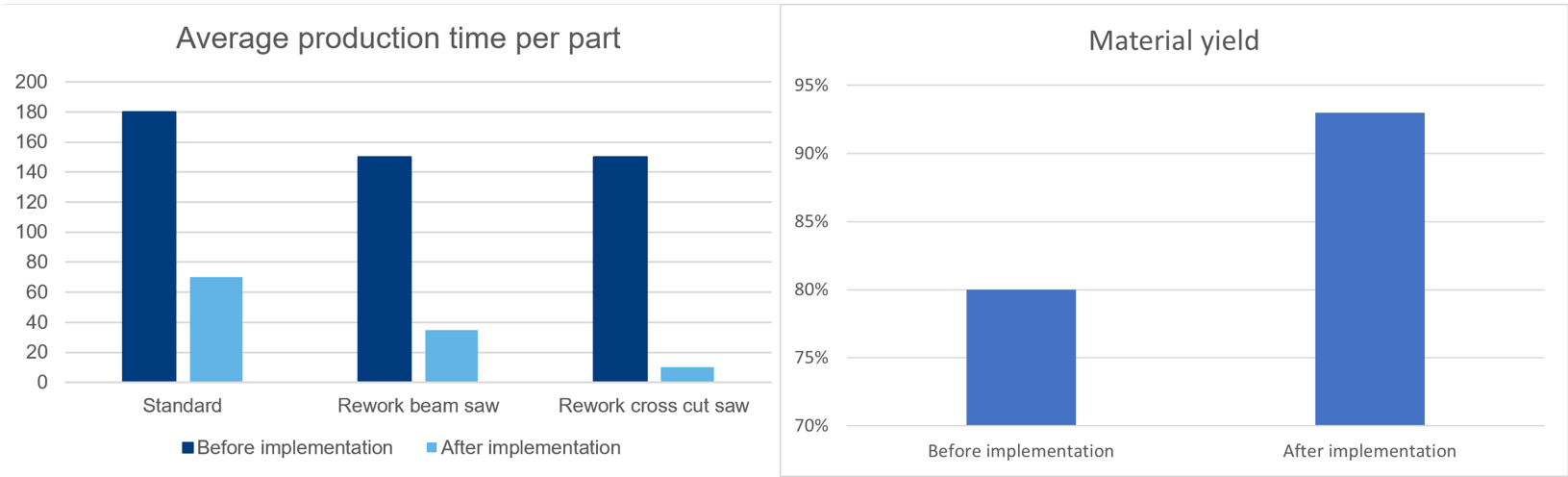

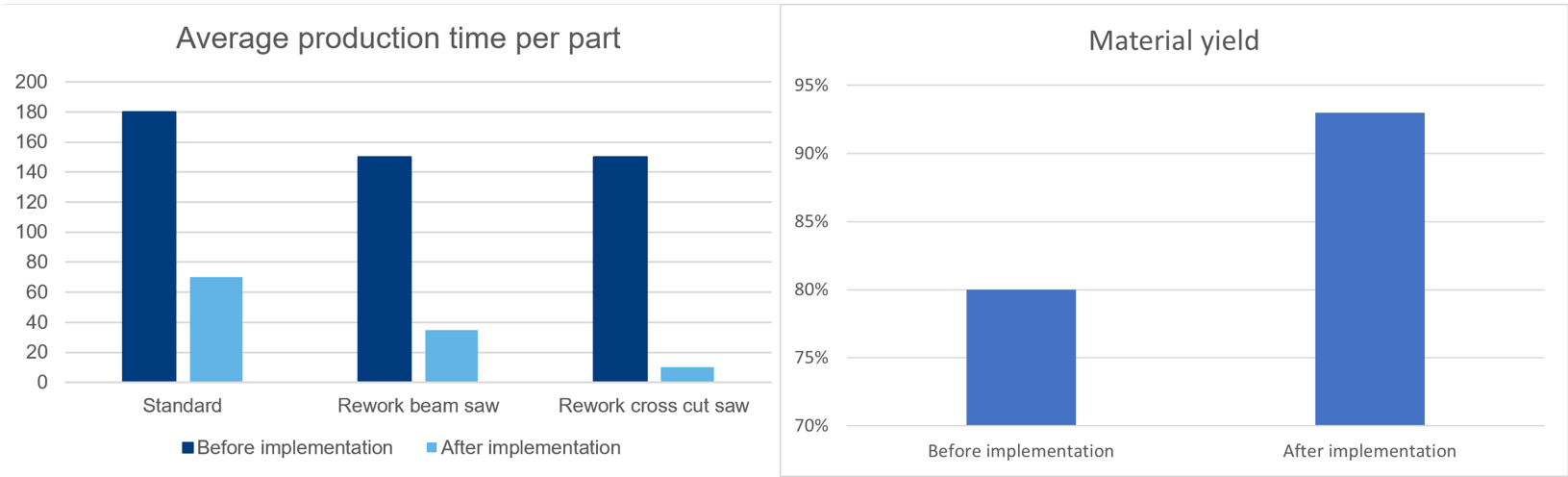

Van Hoecke has been working with ARDIS® to systematically decrease production time and increase material yield. With great success!

The key to success here was to build a seamless data flow connection between the Winstore automatic warehouse, the Selco beam saw and the Tiger Stop cross cut saw. Every fifteen minutes a new batch is released for production. ARDIS® OPTIMIZER automatically generates the correct data for each of the three machines.

At each work station a big screen informs operators on the current status of all jobs to be processed. In the picture you see the Selco beam saw that cuts the strips, which are then cut into parts by the Tiger Stop crosscut saw. Completely in sync with the movement of sheets, strips and parts, ARDIS® PERFORM pumps all relevant job information through the screens at each work station. The jobs marked in red are rush orders, getting absolute priority. This way the operators know exactly what to do. The instant communication between the office and the shop floor makes life easier for everyone!